Human activities have utilized wind power throughout centuries for grain processing purposes as well as electric power production. Modern society relies on wind turbines as essential components for realizing sustainable global energy production. The guide provides an introduction to wind turbine fundamentals and best manufacturing and maintenance standards which will build your understanding of wind energy capabilities.

Fundamental Knowledge of Wind Turbine Technology Must Be Grasped

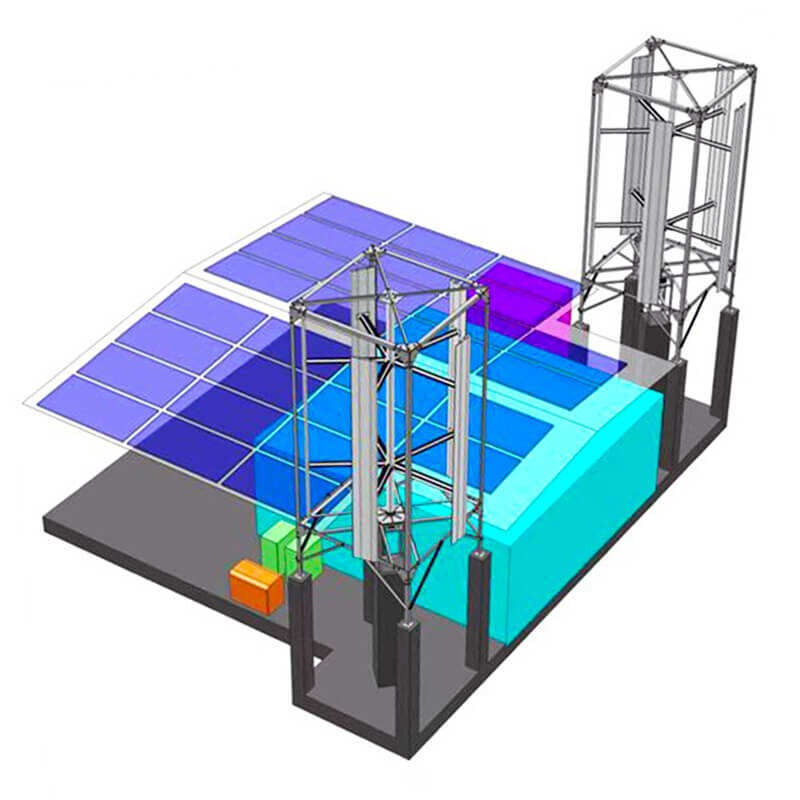

To comprehend wind turbine technology properly one needs to learn about the essential elements which power wind turbine systems. The mechanical power transformation of wind turbine systems starts with the harnessing of wind kinetic energy which produces electricity output.

Mastering wind turbine technology through education will create both future learning possibilities and enhance ability to handle problems and improve system efficiency as a manufacturing or maintenance professional.

Best Practices for Manufacturing and Maintenance

Manufacturing a lasting operational wind turbine needs strict planning combined with strict manufacturing standards. Wind facilities need maintenance activities to achieve long-lasting operational readiness.

Advanced composites used for blades improve both durability along with performance outcomes. Material selection requirements emphasize proper identification for environmental stressful conditions. High manufacturing precision makes certain that assembled mechanisms work without issues when operating across different environmental conditions. The operation with proper fitment minimizes the strain that elements experience. Product testing starts during different manufacturing phases thus enabling early defect detection. NDT can be used as a non-destructive method to verify the structural integrity of essential components.

The use of sustainable manufacturing alongside recycling operations minimizes environmental harm generated by the wind turbine production cycle.

Regular inspections alongside diagnostic analyses help in discovering potential faults in advance. The primary inspection focus goes to blades and both electrical connections along with mechanical parts of the system. The maintenance of lubrication systems alongside the maintenance of coolant systems plays a critical role in supporting smooth functioning of gearboxes along with moving parts.

Advanced Tips for Optimizing Performance

After implementing base practice manufacturing and maintenance procedures you can continue by putting more advanced steps into action to enhance turbine efficiency.

Selecting a site with lasting strong winds combined with low turbulence requires utmost importance for turbine success. Turbine performance optimizes energy capture across different wind conditions through the use of advanced pitch control systems adjusting the blade angles.

To become a master of wind turbines one needs full technology knowledge while mastering best production techniques and performing regular maintenance duties. Implementing these recommendations will allow you to participate actively in building sustainable wind energy operations so you achieve professional success in wind energy development.